2025-03-31 15:17:55

Application of EPDM high strength textile rope hose

EPDM high-strength textile rope hose is a composite hose with EPDM as the base material and a high-strength synthetic fiber (such as polyester, nylon or aramid) braided layer embedded in it. Its core design combines the weather resistance of EPDM with the mechanical strength of the textile reinforcement layer, and is widely used in industrial scenarios that require pressure resistance, aging resistance and dynamic bending. Compared with PTFE hoses, EPDM hoses are lower in cost, but slightly inferior in chemical corrosion resistance.

2. Core features and advantages

Excellent weather resistance:

Ozone/UV resistance: Outdoor service life is up to 8~10 years, and the UV radiation intensity is >1000W/m², which is suitable for open-air equipment (such as hydraulic pipelines of construction machinery).

Wide temperature range adaptability: Working temperature -50℃~+150℃, short-term temperature resistance can reach 170℃, covering the needs of cold to tropical climates.

Outstanding mechanical properties:

Compressive strength: Multi-layer polyester rope 45° cross-braided reinforcement, bursting pressure reaches 4.0~6.0MPa (2~3 times that of ordinary rubber tube).

Anti-twist deformation: Dynamic bending radius ≤ 3 times the tube diameter, withstand 100,000 bending cycles without cracking (in line with ISO6803 standard).

Media compatibility:

Resistant to water, steam, weak acid/alkali (such as 10% sulfuric acid, 5% sodium hydroxide solution), but not resistant to oil and hydrocarbon solvents (need to use NBR or FKM hose instead).

Safety and environmental protection:

Complies with ROHS and REACH regulations, no halogen/heavy metal precipitation, and passed drinking water standard certification (such as WRAS, KTW).

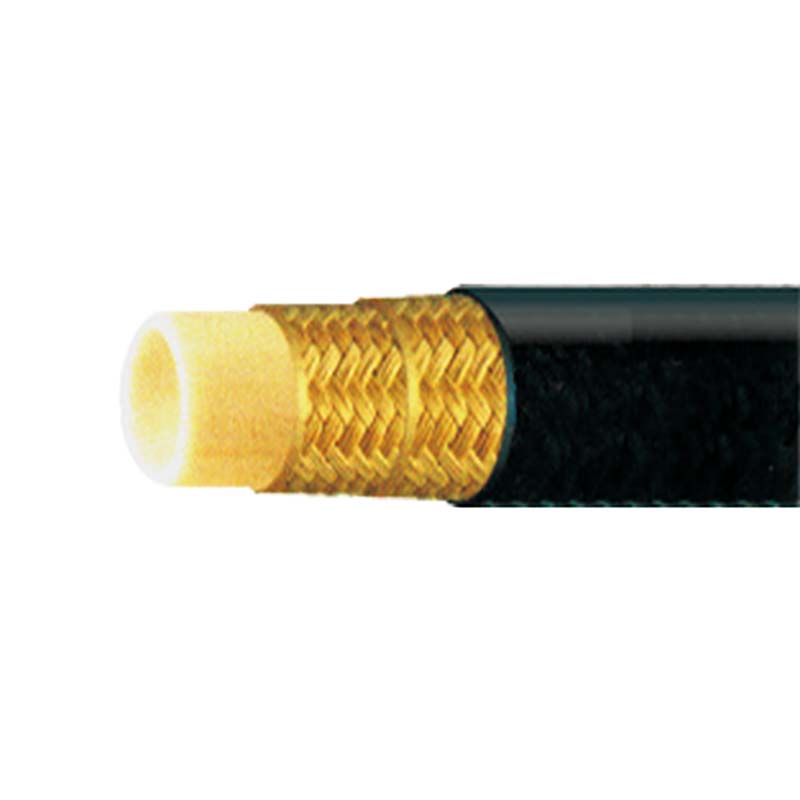

3. Typical structural design Inner rubber layer: 2~4mm thick EPDM rubber, resistant to medium penetration (oxygen permeability <0.1g/m²·24h).

Reinforcement layer: 2~4 layers of high-strength polyester fiber rope, braiding angle 30°~54°, tensile strength ≥200N/mm².

Outer rubber layer: Modified EPDM with carbon black added, wear resistance increased by 40% (Taber wear <100mm³).

IV. Main application areas Automotive industry:

Engine cooling water pipe (resistant to ethylene glycol antifreeze), turbocharger intake hose (resistant to high temperature air).

New energy vehicle battery cooling system (working pressure 0.3~0.8MPa).

Industrial equipment:

Air compressor/hydraulic system pipeline (pressure resistance 4.0MPa, pulse frequency ≤2Hz).

Hot steam transportation (150℃ saturated steam continuous operation >5,000 hours).

Construction and engineering machinery:

Concrete pump truck delivery pipe (resistant to abrasive wear, C30 concrete delivery volume >1 million cubic meters).

Tunnel ventilation system (resistant to moisture and mold, ventilation volume > 10,000m³/h).

Agricultural irrigation:

Mobile sprinkler water supply pipe (resistant to negative pressure -0.09MPa, resistant to field gravel wear).

5. Selection and use recommendations

Media matching:

Avoid contact with hydrocarbons such as gasoline, diesel, and lubricating oil (EPDM swelling rate may be > 20%).

The concentration of acidic media needs to be controlled (pH > 2 or < 12).

Pressure level:

Low pressure scenario (< 1.0MPa): single-layer reinforced hose.

High pressure scenario (> 2.5MPa): double-layer steel wire + fiber composite reinforced structure.

Installation and maintenance:

The minimum bending radius is ≥ 2 times the pipe diameter to prevent the reinforcement layer from breaking.

For outdoor use, the outer rubber layer needs to be checked regularly for aging cracks (pressure testing every 2 years is recommended).

Leave a Comment