2024-11-28 13:51:57

Types and materials of cleaning machine hoses

In daily life and industrial production, cleaning equipment is undoubtedly an important tool for maintaining environmental hygiene and equipment cleanliness. In cleaning equipment, hoses are an essential component, and their quality and function directly affect the effectiveness of cleaning. The cleaning machine hose, as an important component connecting the cleaning machine with the nozzle or cleaning area, how to choose the appropriate hose has become a focus of concern for many users.

What is a cleaning machine hose?

The cleaning machine hose is usually a flexible pipe made of polymer material, installed on the high-pressure cleaning machine, responsible for conveying high-pressure water flow. Due to its high pressure and frequent use requirements, the material, design, and process of the hose have specific requirements. Hoses are mainly used for outdoor cleaning in households, car cleaning, and industrial equipment cleaning.

Types and materials of cleaning machine hoses

There are many types of cleaning machine hoses on the market, which can be mainly divided into the following categories based on their materials:

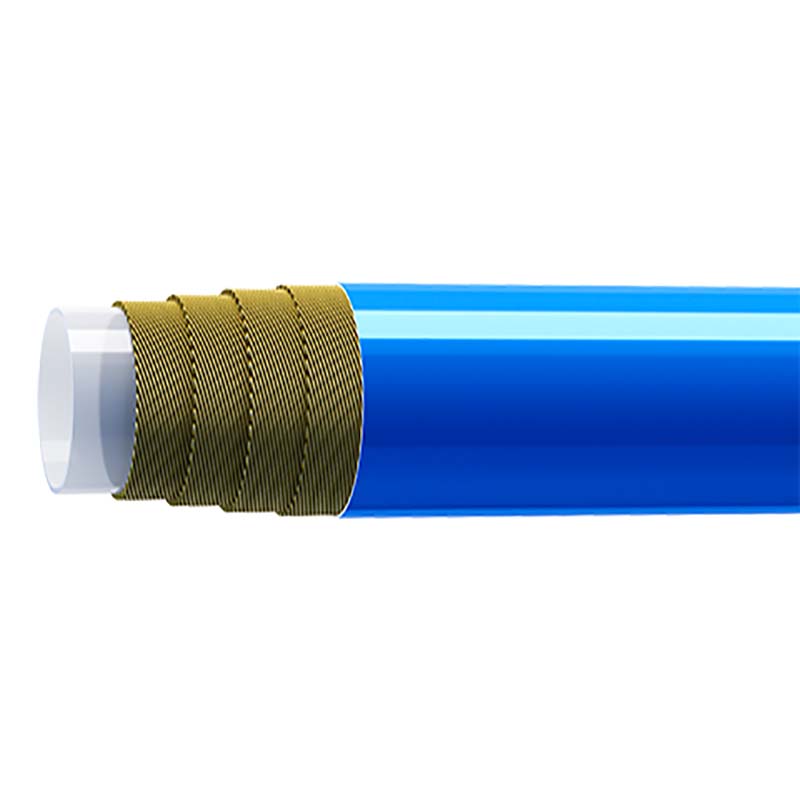

1. Rubber hose

Rubber material has high wear resistance and elasticity, which can effectively resist friction and external pressure. Rubber hoses are commonly used in industrial environments and are suitable for transporting chemical cleaning agents due to their chemical corrosion resistance.

2. Thermoplastic hoses

This type of hose is commonly used in households and small to medium-sized cleaning equipment due to its light weight and ability to withstand high pressure. Thermoplastic hoses are commonly used in household high-pressure cleaning machines and have good durability and environmental adaptability.

3. Stainless steel hose

Stainless steel hoses are widely used in harsh industrial environments due to their strong pressure resistance, heat resistance, and corrosion resistance. They not only provide excellent durability, but also effectively prevent thermal deformation inside the hose.

Factors to consider when choosing a cleaning machine hose

When choosing a suitable cleaning machine hose, in addition to material, users should also consider several key factors.

1. Pressure level

The pressure that the cleaning machine hose can withstand depends on the working pressure of the high-pressure cleaning machine connected. The pressure requirements for hoses vary in different application scenarios. When selecting, ensure that the pressure resistance of the hose is higher than the maximum output pressure of the cleaning machine.

2. Length

The length of the hose determines the size of the cleaning range. Household cleaning usually requires hoses of 10 to 15 meters to meet the needs, while industrial use may require longer hoses to handle large-scale cleaning tasks.

3. Temperature tolerance

If hot water is required during the cleaning process, the temperature tolerance of the hose becomes particularly important. Stainless steel hoses are commonly used in high-temperature environments to ensure stability and safety during operation.

4. Connection method

The connection method of the hose affects the convenience of installation and use. Common connection methods include snap on, threaded, etc. Users should choose the appropriate connection method based on the specific interface of the device.

Maintenance and upkeep of cleaning machine hoses

Regular maintenance and upkeep are essential to extend the service life of the cleaning machine hose.

1. Check for wear and tear

Regularly check the wear level of the hose, especially the connection between the hose and the joint, as well as the outer surface that is often exposed to sharp objects and chemicals. Timely replace damaged hoses to prevent safety hazards.

2. Storage conditions

Leaving direct sunlight and extreme temperatures can effectively prevent hose aging. After use, the hose should be rolled up and placed in a cool and ventilated place.

3. Cleaning and rinsing

Thoroughly clean the inside and outside of the hose after use, remove residual dirt and chemicals, and reduce erosion of the hose.

4. Prevent excessive stretching

During use, avoid excessive stretching or twisting of the hose, as this can damage the inner wall structure of the hose and reduce its service life.

Technological innovation leads the development of hoses

With the continuous advancement of technology, the technology of cleaning machine hoses is also constantly developing. Some innovative hoses have improved their corrosion resistance, pressure resistance, and flexibility through the introduction of new materials and technologies. For example, using nanomaterials to enhance the physical properties of hoses, as well as improving the compression strength of hoses through lamination technology, provide users with better choices.

The cleaning machine hose is no longer just a simple conveying tool, but a combination of efficient cleaning and energy-saving environmental protection. In the near future, we will witness the emergence of more intelligent and automated hose systems, bringing users a more convenient and efficient user experience.

summary

As an indispensable part of cleaning equipment, the performance of the cleaning machine hose directly affects the efficiency and effectiveness of cleaning. When selecting and using hoses, users need to fully consider their purpose, material, pressure resistance, and environmental adaptability. Meanwhile, through appropriate maintenance and upkeep measures, the service life of the hose can be effectively extended. In the future, through technological innovation, the performance of hoses will be further improved, providing more reliable support for various cleaning tasks.

Leave a Comment